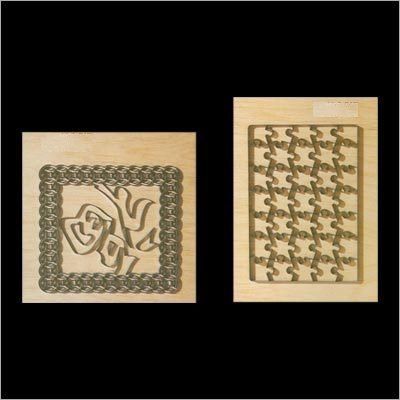

Puzzle Die

Puzzle Die Specification

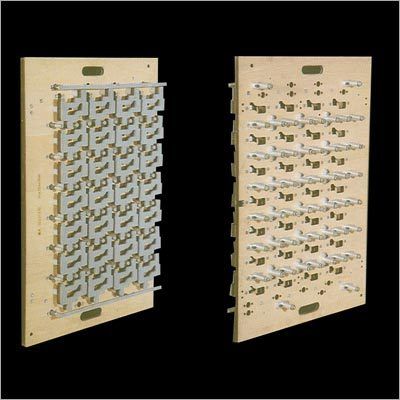

- Working Process

- Precision CNC Machining

- Core Material

- High Speed Steel

- Tolerance

- 0.005 mm

- Life Span

- Up to 10 Million Strokes

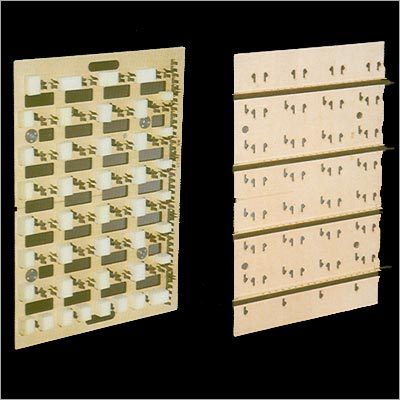

- Mould Base

- Mild Steel

- Material

- Alloy Steel

- Shaping Mode

- Press Die

- Punch Dies

- Hardened Steel

- Die Head

- Customized

- Packaging

- Wooden Box

- Cavity

- Single or Multi Cavity Options

- Processing Type

- EDM, Grinding, Milling

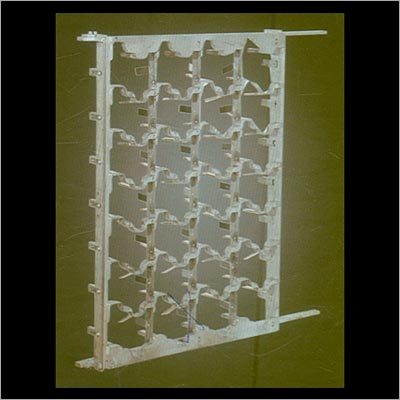

- Operating Temperature

- Up to 250°C

- Surface Finish

- Polished

- Application

- Industrial Puzzle Cutting

- Design

- Customizable Shapes

- Dimension

- Standard and Custom Sizes Available

- Heat Treatment

- Vacuum Hardened

About Puzzle Die

To meet the various requirements of our customers, we are offering supreme grade Puzzle Die. The die machines which we offer are generally used for cutting and shaping of diamonds. These can also be used for adding patterns and designs to various other hard materials. Quality components and materials are used in the manufacturing process to manufacture durable and sturdy machines. Our high-ranking officials ensure quality products to our clients by testing every Puzzle Die before delivery.

Features:

-

Durable

-

Low power consumption

-

Easy to use

-

Sturdy design

Customizable and Durable Industrial Solution

Solve your industrial puzzle cutting needs with our customizable puzzle die, available in both single and multi-cavity configurations. Its robust construction and precision machining make it a reliable choice for sustained production under challenging conditions.

Engineered for Precision and Longevity

Crafted using advanced processes like EDM and CNC machining, the die offers tight tolerances and a polished finish. The vacuum-hardened alloy steel ensures enduring performance, while the custom design flexibility supports diverse manufacturing demands.

Safe Packaging and Efficient Supply

Each puzzle die is secured in high-quality wooden packaging, ensuring safe delivery. As a trusted supplier and exporter in India, we serve dealers, manufacturers, and distributors, offering prompt and reliable support for your business.

FAQs of Puzzle Die:

Q: How does the vacuum hardening process enhance the dies performance?

A: Vacuum hardening significantly increases the wear resistance and overall durability of the die, allowing it to achieve a long lifespanup to 10 million strokeswhile maintaining precise tolerances during industrial puzzle cutting.Q: What are the available customization options for the puzzle die design?

A: We offer fully customizable shapes, dimensions (standard and custom), single or multi-cavity choices, and specialized die head and punch dies to suit specific production requirements. Custom design consultations ensure the die fits your unique application.Q: When should I consider using a multi-cavity die for puzzle cutting?

A: Multi-cavity dies are ideal when higher production volumes or shorter cycle times are required, as they allow multiple parts to be produced in a single operation. This is especially beneficial for large-scale industrial applications.Q: Where is this puzzle die typically used within the industry?

A: This die is widely employed in industrial settings where precise puzzle cutting is necessary, such as in the production of custom packaging inserts, educational toys, and specialized component manufacturing.Q: What is the recommended operating temperature for this die?

A: The die is designed to operate effectively at temperatures up to 250C, ensuring stability and consistent results even under demanding process conditions.Q: How is packaging handled to ensure the die arrives safely?

A: Each puzzle die is securely packaged in a sturdy wooden box, protecting it from physical damage and environmental factors during transport and storage.Q: What are the primary benefits of using this puzzle die in manufacturing?

A: Its high precision, long operational life, customizable configurations, and robust materials significantly enhance productivity, reduce downtime, and lower long-term replacement costs for manufacturers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dies & Moulds Category

Blanking Dies

Working Process : Stamping and Cutting, Other

Shaping Mode : Other, Manual and CNC

Punch Dies : High Precision

Core Material : Steel

Die Head : Standard Die Head

Material : Other, Plasticcoated woodbased structure

Corrugated Box Die

Working Process : Other, Automated and Manual Cutting

Shaping Mode : Other, Customizable Shaping

Punch Dies : Highperformance punch dies

Core Material : Highquality plywood

Die Head : Precision Die Head

Material : Other, Steel and Wood

Stamping Dies

Working Process : Other, Metal Stamping

Shaping Mode : Cold extrusion, Other

Punch Dies : Highdensity alloy

Core Material : Steel

Die Head : Precision Die Head

Material : Other, Highstrength steel

Industrial Laser Dies

Working Process : Continuous Operation, Other

Shaping Mode : Other, Automated Laser Shaping

Punch Dies : Laserenhanced Punch Dies

Core Material : Steel Alloy

Die Head : High Precision Die Head

Material : Other, Industrialgrade Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS