Laser Die

Laser Die Specification

- Tolerance

- 0.01 mm

- Mould Base

- Mild Steel

- Core Material

- Alloy Steel

- Working Process

- Laser Cutting, CNC Machining

- Life Span

- Up to 1,000,000 shots

- Material

- Steel

- Shaping Mode

- Punching Mold

- Punch Dies

- Customizable

- Die Head

- Available

- Dimensions

- As per client specification

- Die Type

- Laser Cutting Die

- Surface Finish

- Polished

- Heat Treatment

- Available as required

- Packaging

- Export standard packaging

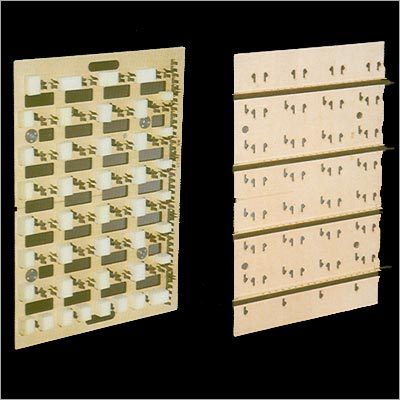

- Cavity

- Single or multiple as per requirement

- Application

- Industrial Cutting

About Laser Die

Depending on our well-equipped infrastructure facility, we capable of manufacturing high quality Laser Die. The offered dies are used to print and design intricate patterns on various types of materials. Owing to its high performance and low energy consumption, these machines are widely demanded by our customers. Our qualified team members make use of modern machines and techniques to manufacture Laser Die of latest technology. These machines are generally used in automobile and machinery industries for cutting various component parts.

Features:

-

Low maintenance

-

Rigid design

-

Easy to operate

-

Efficient functionality

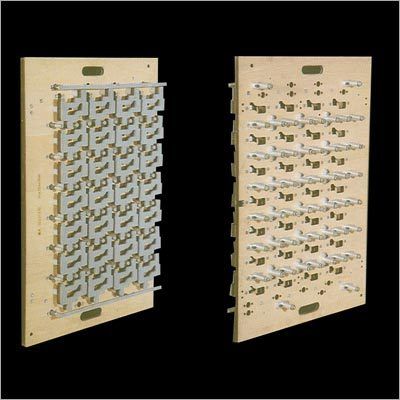

Superior Surface Finish and Precision Engineering

Our Laser Cutting Dies undergo a meticulous polishing process, resulting in consistent surface quality that enhances die performance. Precision engineering and advanced CNC machining ensure each die meets stringent tolerance levels, suitable for high-demand industrial environments. The customizable cavities and punch dies offer flexibility to address specific cutting requirements.

Customizable to Meet Diverse Industrial Needs

Clients benefit from a wide array of customization options including die dimensions, cavity configuration, heat treatment, and punch die shapes. Whether your requirement is for a single die or a complex multi-cavity design, our team supports complete personalization to fit your industrial cutting process, maximizing efficiency and reliability.

Durable Construction and Extended Life Span

Our dies are built with alloy steel cores and mild steel bases, offering strength and reliability for rigorous cutting operations. Heat treatment is available to further boost durability and die life. Each product is designed to deliver up to 1,000,000 shots, ensuring longevity and reduced maintenance costs for industrial users.

FAQs of Laser Die :

Q: How is the surface finish achieved on your Laser Cutting Dies?

A: The polished surface finish is accomplished using advanced finishing techniques during manufacturing, ensuring smooth edges and minimal friction during cutting, which results in clean and precise outputs.Q: What customization options are available for these Laser Cutting Dies?

A: Clients can specify dimensions, cavity configurations, heat treatment, and punch die designs according to their requirements. Our dies can incorporate single or multiple cavities and are manufactured to match custom specifications.Q: Where can these Laser Cutting Dies be used?

A: These dies are designed for industrial cutting processes and are suitable for use in manufacturing plants, production facilities, and any operation requiring precise and efficient metal shaping.Q: What is the typical process for manufacturing the Laser Cutting Dies?

A: Manufacturing involves high-precision laser cutting and CNC machining to achieve exact shapes and tolerances. Polishing and optional heat treatment further refine the die for enhanced performance and durability.Q: When should heat treatment be considered for my die order?

A: Heat treatment is recommended when increased hardness and wear resistance are required, particularly for high-volume or abrasive cutting applications. We provide heat treatment as per client specifications to optimize lifespan.Q: What benefits do these Laser Cutting Dies offer for industrial usage?

A: They provide exceptional accuracy with tight tolerance (0.01 mm), long service life of up to 1,000,000 shots, flexibility in customization, and reliable performance, making them highly cost-effective for industrial clients.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dies & Moulds Category

Corrugated Box Die

Working Process : Other, Automated and Manual Cutting

Core Material : Highquality plywood

Life Span : 5 Years

Die Head : Precision Die Head

Mould Base : Solid Steel Base

Material : Other, Steel and Wood

Acrylic Cutting Die

Working Process : Other, Laser Cutting and Shaping

Core Material : Acrylic

Life Span : High durability

Die Head : Precision Laser Die Head

Mould Base : Steel

Material : Acrylic, Other

Industrial Laser Dies

Working Process : Continuous Operation, Other

Core Material : Steel Alloy

Life Span : 5 Years

Die Head : High Precision Die Head

Mould Base : Robust Metal Base

Material : Other, Industrialgrade Stainless Steel

Blanking Dies

Working Process : Stamping and Cutting, Other

Core Material : Steel

Life Span : High Durability

Die Head : Standard Die Head

Mould Base : Custom Design

Material : Other, Plasticcoated woodbased structure

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS