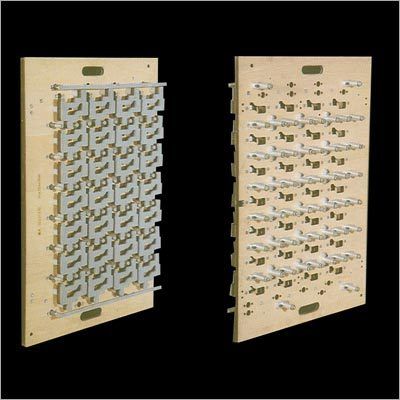

Laser Cutting Die

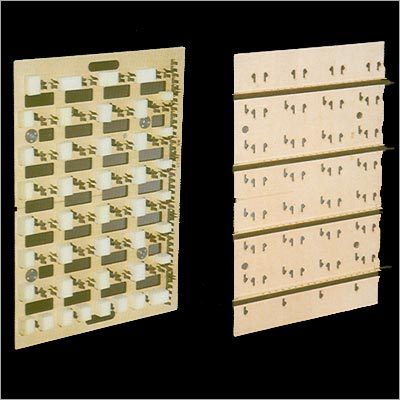

Laser Cutting Die Specification

- Core Material

- Tool Steel

- Working Process

- Laser Cutting

- Life Span

- Up to 300,000 strokes

- Tolerance

- 0.01 mm

- Material

- Steel/Wood/Composite

- Shaping Mode

- Die Cutting

- Punch Dies

- Custom Configurable

- Die Head

- Precision Machined

- Application

- Paper, Leather, Plastic, Rubber, Foam, and Cardboard processing

- Production Capacity

- 1000 pieces per month

- Blade Type

- High Precision Steel Rule Blade

- Operating Temperature

- 0°C to 60°C

- Mounting Type

- Flatbed or Rotary

- Edge Hardness

- ~60 HRC

- Weight

- Depends on size and configuration

- Design Type

- Customized as per client drawings

- Cutting Thickness

- Up to 20 mm, depending on material

About Laser Cutting Die

Empowered by vast infrastructural facilities, we are able to manufacture top quality Laser Cutting Die. These cutting dies are used to cut materials like steel and wood into different shapes and designs. The offered machines are designed by making use of modern techniques and high-grade materials, obtained from the renowned vendors of the industry. To meet the various requirements of our customers, we are able to offer the Laser Cutting Die in many sizes and specifications.

Features:

-

High performance

-

Durable

-

Low maintenance

-

Easy to operate

Superior Precision for Diverse Applications

Designed to handle a wide array of materialsincluding paper, leather, plastics, rubber, foam, and cardboardthis customized laser cutting die offers high accuracy and flexibility for various industries. Advanced laser technology ensures clean edges, while tailored designs support unique production needs.

Engineered for Durability and Performance

Constructed from tool steel and featuring a high-precision steel rule blade with an edge hardness of 60 HRC, the die is capable of sustaining up to 300,000 strokes without compromising on quality. This makes it an ideal choice for long-term, intensive operations in commercial and industrial settings.

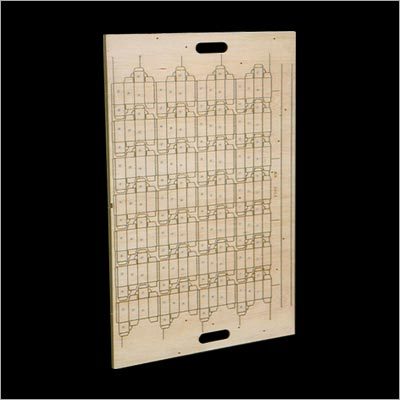

Custom Solutions with Advanced Technology

With the ability to create dies according to client drawings, combined with laser cutting processes and custom-configurable punch dies, the product adapts perfectly to specific requirements. Flatbed and rotary mounting options further enhance its application versatility across varying manufacturing environments.

FAQs of Laser Cutting Die:

Q: How is a laser cutting die customized for specific production requirements?

A: Each laser cutting die is crafted according to client-supplied drawings, allowing for complete customization of blade patterns, punch dies, and overall dimensions. This ensures precise compatibility with unique application or machinery needs.Q: What materials can be processed using this laser cutting die?

A: This die is suitable for cutting paper, leather, plastic, rubber, foam, and cardboard, making it versatile for industries such as packaging, automotive, textiles, and more.Q: When should I choose a flatbed versus a rotary mounting type?

A: A flatbed mounting is best for processing thicker or rigid materials and lower production speeds, while rotary mounting offers higher speed and is ideal for continuous, roll-based materials or high-volume runs.Q: Where can this product be sourced in India?

A: The laser cutting die is available through a wide network of dealers, distributors, exporters, importers, manufacturers, service providers, suppliers, traders, and wholesalers across India.Q: What is the typical lifespan and maintenance required for this die?

A: With an edge hardness of around 60 HRC and robust core material, the die can achieve up to 300,000 strokes under optimal conditions. Regular inspection and proper handling can further extend its operational lifespan.Q: How does the laser cutting process enhance die cutting performance?

A: Laser cutting enables high precision with minimal material distortion, producing clean, consistent edges and allowing for tight tolerances of 0.01 mm, which significantly improves product quality and reduces waste.Q: What are the main benefits of using a high-precision steel rule blade in die cutting?

A: The high-precision steel rule blade delivers accurate and repeatable cuts, leading to superior edge quality, minimized downtime, and efficient processing across various materials.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dies & Moulds Category

Industrial Laser Dies

Material : Other, Industrialgrade Stainless Steel

Shaping Mode : Other, Automated Laser Shaping

Mould Base : Robust Metal Base

Tolerance : 0.1mm

Die Head : High Precision Die Head

Punch Dies : Laserenhanced Punch Dies

Blanking Dies

Material : Other, Plasticcoated woodbased structure

Shaping Mode : Other, Manual and CNC

Mould Base : Custom Design

Tolerance : 0.01 mm

Die Head : Standard Die Head

Punch Dies : High Precision

Duplex Carton Die

Material : Other, Duplex Carton

Shaping Mode : Other, Cutting and Creasing

Mould Base : Standard

Tolerance : High Precision

Die Head : Flat

Punch Dies : Precision Steel

Corrugated Box Die

Material : Other, Steel and Wood

Shaping Mode : Other, Customizable Shaping

Mould Base : Solid Steel Base

Tolerance : 0.01 mm

Die Head : Precision Die Head

Punch Dies : Highperformance punch dies

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS