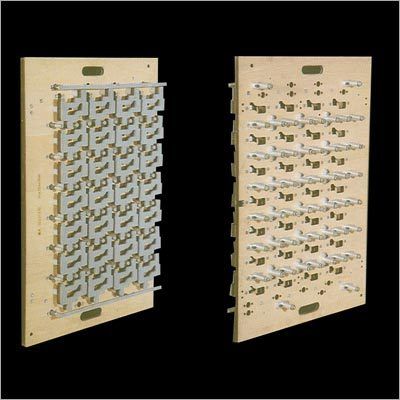

Punching Die

Punching Die Specification

- Core Material

- Hardened Tool Steel

- Life Span

- Up to 500,000 Punches

- Working Process

- Punching, Blanking, Forming

- Tolerance

- 0.01 mm

- Material

- Alloy Steel / Carbide

- Shaping Mode

- Punching Mould

- Punch Dies

- Interchangeable, Precision Ground

- Die Head

- Standard Punching Die Head

- Applications

- Sheet Metal Fabrication, Automotive, Electrical

- Cutting Edge Clearance

- Optimized for Precise Cutting

- Finish Type

- Corrosion Resistant Finish

- Surface Finish

- Polished / Coated for Wear Resistance

- Assembly Method

- Standard / Modular

- Production Capacity

- High Volume, Continuous Operation

- Die Size

- Customizable as per Requirement

About Punching Die

Years of involvement in this field has enabled us to manufacture Punching Die. The offered products are used to die various fabrics and materials with the use of punching machines. These machines are manufactured according to technology advancement in the industry. High-grade components and materials are used in the manufacturing process for manufacturing durable and high performance Punching Die. During the manufacturing process, our team members are guided by expert professionals to ensure flawless end products.

Features:

-

Durable

-

Easy to operate

-

High performance

-

Corrosion resistant

Precision Manufacturing for Diverse Industries

This Punching Die is designed to excel in sheet metal fabrication, automotive parts, and electrical applications, handling complex shapes with high accuracy. Optimized for continuous high-volume runs, it maintains stringent tolerances, making it ideal for mass production and critical components. Its robust construction and adaptable modular design offer versatility for manufacturers, suppliers, and service providers seeking reliable forming solutions.

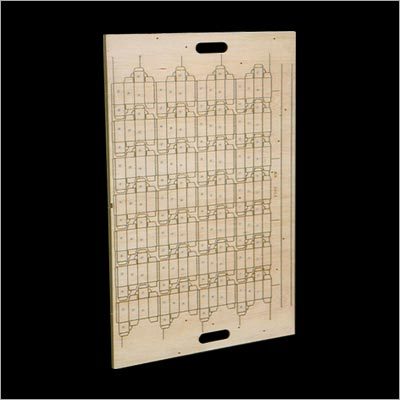

Enhanced Durability and Surface Finish

Featuring a polished or coated surface, the Punching Die provides superior resistance to wear and corrosion. Hardened tool steel and alloy steel or carbide materials ensure a long service life, withstanding up to 500,000 punching operations. The corrosion-resistant finish maintains quality, while precision ground components contribute to dependable results across repeated usage.

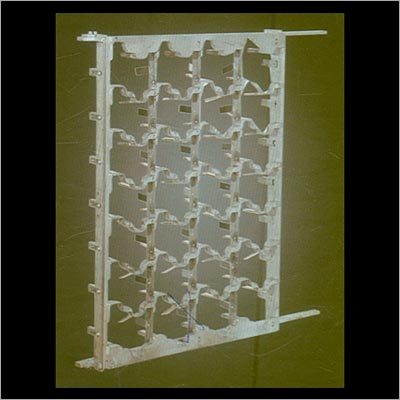

Customization and Versatile Assembly

Die size and cutting edge clearance can be customized according to production needs, providing tailored solutions for specific projects. The interchangeable die heads and modular assembly enable rapid adaptation and simplified maintenance, making this die suitable for various sheet metal processes, including punching, blanking, and forming. Its standardized features meet the demands of manufacturers, exporters, and importers in India.

FAQs of Punching Die:

Q: How is the Punching Die utilized in sheet metal fabrication and automotive manufacturing?

A: The Punching Die is used to precisely cut, blank, and form metal sheets into desired shapes for applications in sheet metal fabrication, automotive body panels, structural components, and electrical enclosures, where accuracy and endurance are critical.Q: What benefits does the polished or coated surface offer for wear resistance and durability?

A: A polished or coated finish protects the die from friction-induced wear and corrosion, prolongs its operational life, and ensures consistent, high-quality results even in demanding, continuous production environments.Q: When should I choose a customized die size and cutting edge clearance?

A: Custom die size and optimized edge clearance are best selected when precise tolerances or unique part dimensions are required, allowing manufacturers to achieve the exact specifications and high accuracy needed for specialized projects.Q: Where can I source the Punching Die in India?

A: The Punching Die is available through a wide network of dealers, distributors, manufacturers, suppliers, and service providers across India, ensuring accessibility for both domestic purchasers and international exporters or importers.Q: What is the process involved in maintaining or replacing punch dies during high-volume operations?

A: The modular assembly and interchangeable punch dies allow for swift replacement or maintenance, minimizing downtime. This feature is advantageous for continuous operations, enabling efficient upkeep without major disruptions.Q: How does the corrosion-resistant finish benefit production in humid or challenging environments?

A: The corrosion-resistant finish safeguards the die against moisture and harsh conditions, preserving its precision and structural integrity, which is essential for metal-forming processes in humid climates or rigorous industrial settings.Q: What is the expected lifespan and production capacity of the Punching Die?

A: Constructed from hardened tool steel and alloy steel or carbide, the die achieves a lifespan of up to 500,000 punches while supporting high-volume, continuous operationmaking it cost-effective for large-scale manufacturing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dies & Moulds Category

Blanking Dies

Mould Base : Custom Design

Tolerance : 0.01 mm

Die Head : Standard Die Head

Shaping Mode : Other, Manual and CNC

Working Process : Stamping and Cutting, Other

Punch Dies : High Precision

Stamping Dies

Mould Base : Standard Mould Base

Tolerance : 0.01 mm

Die Head : Precision Die Head

Shaping Mode : Cold extrusion, Other

Working Process : Other, Metal Stamping

Punch Dies : Highdensity alloy

Duplex Carton Die

Mould Base : Standard

Tolerance : High Precision

Die Head : Flat

Shaping Mode : Other, Cutting and Creasing

Working Process : Other, Manual and Automatic Machines

Punch Dies : Precision Steel

Industrial Laser Dies

Mould Base : Robust Metal Base

Tolerance : 0.1mm

Die Head : High Precision Die Head

Shaping Mode : Other, Automated Laser Shaping

Working Process : Continuous Operation, Other

Punch Dies : Laserenhanced Punch Dies

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS